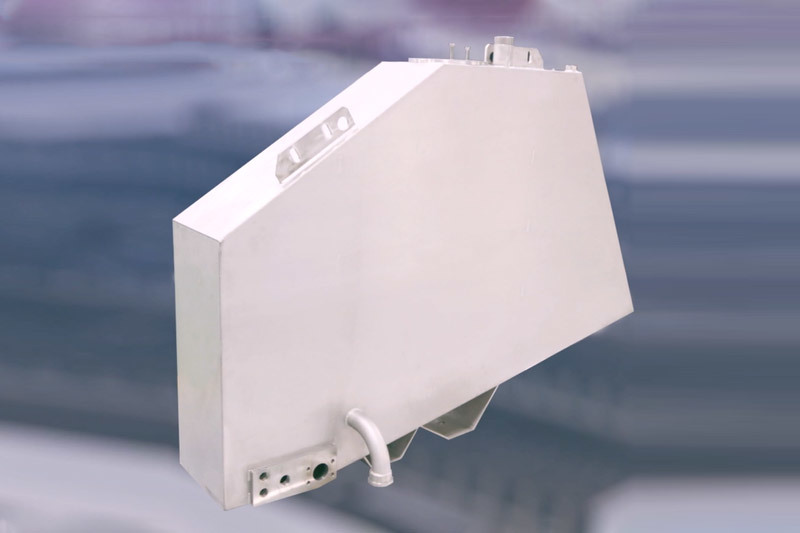

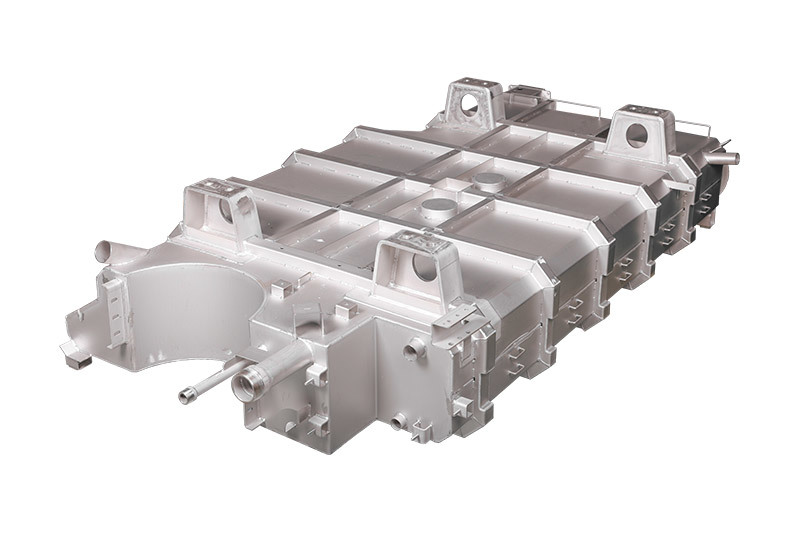

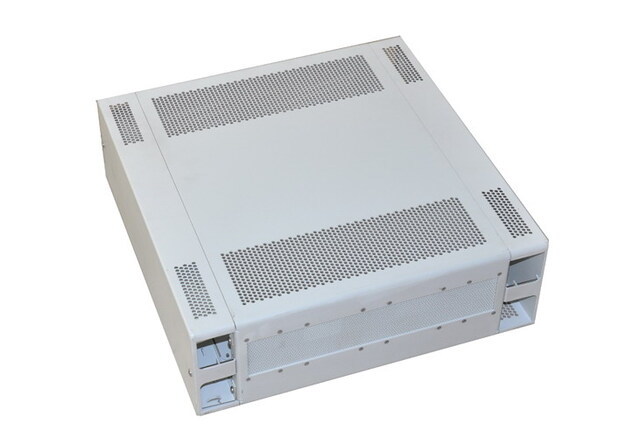

OUR PRODUCTS

Recommend

SINCE 1999

ABOUT US

About Haibo

QingDao Haibo Punching & Sheet Metal Co., LTD was founded in 1999, which engages in stamping, sheet metal, welding, painting finishing, painting and other metal sheet forming. It locates in Qingdao Jimo west industrial park, which is close to Jiaozhouwan high-speed road, Qingyin high-speed road, Qingwei high-speed road, and Qingdao JiaoDong airport. Convenient traffic condition and beautiful environment make a geographic position superiority for our company.

The company was established in 1999

The company covers an area of over 50000 square meters

More than 60 R&D technical talents

Registered capital of 10.29 million yuan

EQUIPMENT

Processing Equipment

APPLICATIONS

Industry Applications

NEWS CENTER

News

2024-04-14

How to carry out waterproof and dustproof processing for cabinet enclosures?

2024-04-14

The Ten Characteristics of Chassis Cabinets

2024-04-14

How to remove burrs after processing metal sheets

2024-04-14

Qingdao Haibo explains stamping technology